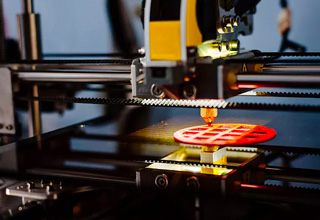

Rotomolding could make small product at the size of 10mm only and could make large product at meters like big chemical containers made by Rock N Roll machine, so offering great variety the sizes. However, rotomolding has much more advantage at big/large size of products rather than small for its labor and time consumption.

English

English 日本語

日本語 français

français Deutsch

Deutsch italiano

italiano العربية

العربية русский

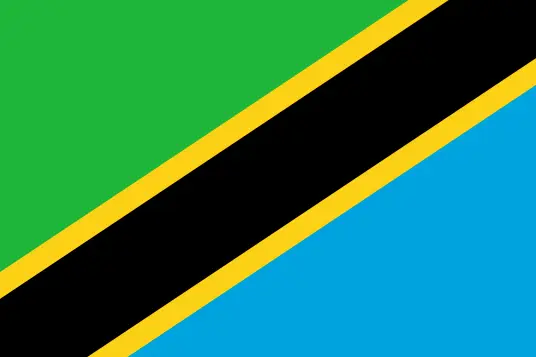

русский Kiswahili

Kiswahili română

română Svenska

Svenska dansk

dansk Español

Español português

português Hausa

Hausa