Crafted from 100% recyclable plastics and enhanced with anti-static and anti-scratch chemical compounds, our moulding carpet extractor attachments ensure durability and sustainability. The mold has already produced 12,000 pieces and continues to perform flawlessly. We offer high-quality carpet extractor attachments to meet your specific needs.

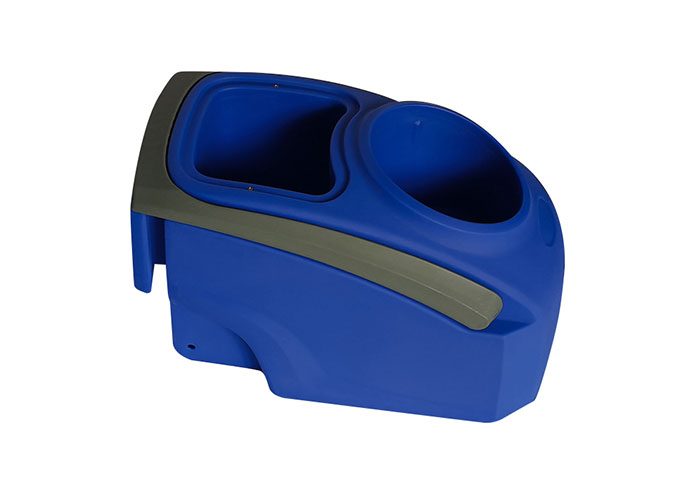

Two deep cavities challenging the heating and cooling of the mold

Both internal and external features need be well controlled.

Limited handle mold space to fill sufficient powder material in for strength connection with body

The carpet extractor attachments are lightweight, making them easy to handle and maneuver during cleaning tasks

The rotational molding process we use is environmentally friendly, producing minimal waste and utilizing recyclable materials.

The manufacturing process of carpet extractor attachments employs advanced rotomolding techniques, which allow for the creation of complex, seamless parts with uniform wall thickness. This method ensures that each attachment is robust and reliable, capable of delivering exceptional performance in various cleaning scenarios.

Once molded, each carpet extractor attachment undergoes rigorous quality control checks to ensure it meets Xiesu's stringent standards. This includes testing for durability, compatibility with different carpet cleaning machines, and overall functionality.

Finally, our carpet extractor attachments are designed for easy integration with a wide range of carpet extractors, providing users with versatile and efficient cleaning solutions. At Xiesu, we are committed to innovation and excellence, ensuring that our all the rotational moulding water tanks including carpet extractor attachments not only meet but exceed industry expectations.